Maintaining Concrete Roads and Sidewalks in Kansas City

Concrete pavements are a cornerstone of the transportation infrastructure in Kansas City, Missouri, providing durable and long-lasting surfaces for roads, highways, and walkways. However, even the most well-designed concrete can succumb to the elements, heavy traffic, and the passage of time, leading to the need for pavement repair and maintenance. As a leading concrete contracting service in the Kansas City area, we understand the importance of proactive and effective concrete pavement repair techniques to keep the city’s roads and sidewalks in top condition.

Concrete Contractor Kansas City has extensive experience in addressing a wide range of concrete pavement issues, from cracking and spalling to joint deterioration and surface irregularities. In this article, we’ll explore the most common concrete pavement repair techniques used in the Kansas City region, providing insights into the benefits, costs, and best practices for each approach.

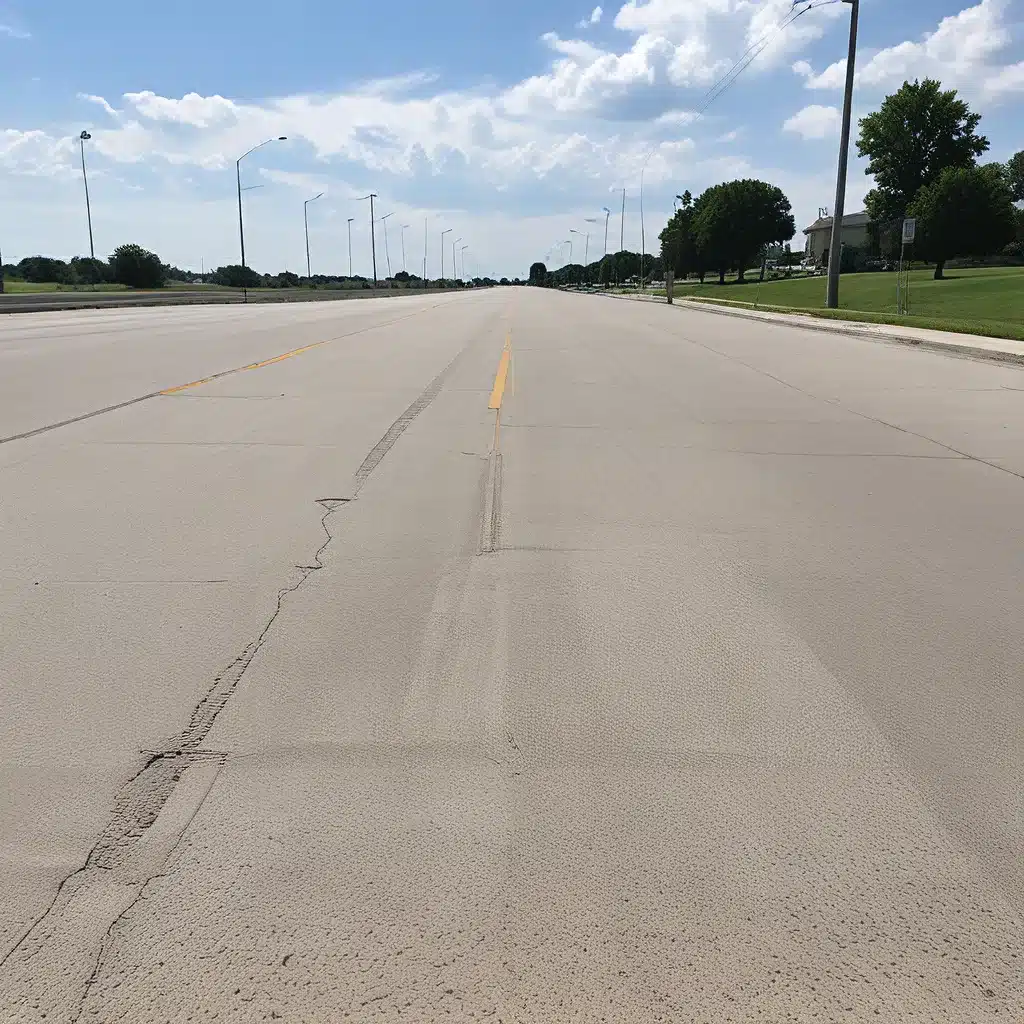

Common Concrete Pavement Problems in Kansas City

Before delving into the repair techniques, it’s important to understand the most prevalent concrete pavement issues faced by the Kansas City area. According to the Missouri Department of Transportation (MoDOT), some of the primary concrete pavement problems in the region include:

-

Cracking: Concrete pavements can develop various types of cracks, such as transverse, longitudinal, and corner cracks, due to factors like subgrade failure, thermal expansion and contraction, and heavy vehicle loads.

-

Spalling: The chipping or breaking of the concrete surface, often occurring around joints and cracks, can lead to further deterioration and pavement failure.

-

Joint Deterioration: The sealant material in concrete pavement joints can degrade over time, allowing water and debris to infiltrate and cause joint failure.

-

Surface Irregularities: Uneven surfaces, such as potholes, depressions, and bumps, can result from a variety of issues, including subgrade settlement, poor drainage, and improper construction.

-

Concrete Scaling: The flaking or peeling of the concrete surface, often caused by exposure to deicing chemicals or freeze-thaw cycles.

Understanding these common problems is crucial in determining the most appropriate concrete pavement repair techniques for the Kansas City region.

Concrete Pavement Repair Techniques

To address the diverse range of concrete pavement issues in Kansas City, a variety of repair techniques are employed. Let’s explore the most widely used methods and their respective benefits:

1. Concrete Patching

Concrete patching is a cost-effective and versatile repair technique used to address localized concrete pavement problems, such as cracks, spalls, and potholes. The process involves removing the damaged concrete, cleaning the affected area, and then filling it with a high-quality concrete mix or a polymer-modified cementitious material. Concrete patching can extend the lifespan of the pavement and improve its appearance, making it a popular choice for residential and commercial concrete surfaces in Kansas City.

Concrete Paving is a critical aspect of this repair technique, as it ensures a smooth, level, and durable finish that blends seamlessly with the existing pavement. The cost of concrete patching can vary depending on the size and complexity of the repair, but it is generally a more affordable option compared to full-depth concrete replacement.

2. Joint Repair and Replacement

Concrete pavement joints play a crucial role in managing expansion and contraction, as well as facilitating load transfer between slabs. Over time, these joints can become deteriorated, allowing water and debris to infiltrate and cause further damage. To address this issue, joint repair and replacement techniques are employed.

Joint repair may involve cleaning and resealing the existing joint material, while joint replacement involves removing the damaged joint and replacing it with a new dowel bar assembly and joint sealant. This process helps to restore the structural integrity of the pavement and prevent future joint-related issues.

The cost of joint repair and replacement can vary depending on the extent of the damage and the size of the project, but it is generally a cost-effective solution to extend the lifespan of the concrete pavement.

3. Full-Depth Concrete Replacement

In cases where the concrete pavement has reached the end of its useful life or has extensive, widespread damage, full-depth concrete replacement may be the most appropriate solution. This technique involves removing the entire concrete slab and replacing it with a new, high-quality concrete mixture.

Full-depth concrete replacement is a more comprehensive and expensive repair option, but it can fully restore the structural integrity of the pavement and provide a long-lasting solution. This technique is often used for heavily trafficked roads, highways, and commercial concrete surfaces in Kansas City, where durability and longevity are of the utmost importance.

The cost of full-depth concrete replacement can vary significantly, depending on factors such as slab size, subgrade conditions, and accessibility. However, the long-term benefits of this repair method, including improved ride quality, reduced maintenance, and enhanced safety, often make it a worthwhile investment for the city’s infrastructure.

4. Concrete Overlays

In some cases, concrete pavement deterioration can be addressed through the application of a concrete overlay, which involves placing a new layer of concrete over the existing pavement. This technique can be an effective solution for minor to moderate distress, such as surface irregularities, minor cracking, and joint deterioration.

Concrete overlays can be cost-effective compared to full-depth replacement, and they can extend the lifespan of the pavement by improving its structural capacity and surface characteristics. This repair method is often used for secondary roads, residential streets, and commercial parking lots in Kansas City, where budget constraints and minimal disruption are key considerations.

The cost of concrete overlays can vary depending on the thickness of the overlay, the existing pavement condition, and the project’s scope. However, this repair technique can provide a durable and long-lasting solution that enhances the overall performance** of the concrete pavement.

5. Surface Treatments

In addition to the more extensive repair techniques, surface treatments can be employed to address specific pavement issues and prolong the lifespan of the concrete pavement. These treatments include:

- Concrete Sealers: Applying a protective sealant to the concrete surface can prevent water infiltration, reduce the effects of weathering, and inhibit the growth of weeds and vegetation.

- Concrete Resurfacing: This process involves applying a thin layer of new concrete over the existing pavement, improving the surface texture and addressing minor irregularities.

- Concrete Grinding and Grooving: These techniques can be used to improve surface friction, reduce tire-pavement noise, and enhance the overall ride quality of the concrete pavement.

Surface treatments are generally less expensive than the more comprehensive repair methods, making them a viable option for maintaining the appearance and performance of residential and commercial concrete surfaces in Kansas City.

Factors Influencing Concrete Pavement Repair Costs

The cost of concrete pavement repair in Kansas City can vary depending on a variety of factors, including:

-

Project Scope: The size and complexity of the repair, as well as the extent of the damage, can significantly impact the overall cost.

-

Material Costs: The price of concrete, joint sealants, and other materials can fluctuate based on market conditions and availability.

-

Labor and Equipment: The labor hours required for the repair, as well as the cost of specialized equipment, can contribute to the overall project budget.

-

Site Accessibility: Factors such as traffic control, the need for lane closures, and site access can add to the overall repair costs.

-

Subgrade Conditions: The stability and quality of the subgrade can affect the repair methods and the amount of preparation work required, thereby impacting the project cost.

-

Warranty and Maintenance: Some concrete pavement repair services may include warranties or ongoing maintenance agreements, which can affect the long-term costs for the property owner.

To obtain accurate estimates for concrete pavement repair in the Kansas City area, it’s best to consult with a reputable concrete contracting service that can assess the specific needs of your project and provide a detailed cost breakdown.

Choosing the Right Concrete Pavement Repair Technique

When selecting the appropriate concrete pavement repair technique for your project in Kansas City, it’s crucial to consider the specific needs of the pavement, the budget constraints, and the long-term performance goals. Concrete Contractor Kansas City can help you evaluate the best solution for your needs, ensuring that your concrete pavement remains durable, safe, and visually appealing for years to come.

By understanding the common concrete pavement problems in the region and the available repair techniques, you can make an informed decision that optimizes the performance and longevity of your concrete surfaces. Investing in proactive and effective concrete pavement repair is an essential step in maintaining the infrastructure of Kansas City’s roads and sidewalks.

Concrete Contractor Kansas City is committed to providing high-quality concrete services and innovative repair solutions to homeowners, businesses, and the city’s public works department. Contact us today to learn more about our concrete pavement repair capabilities and how we can help preserve the integrity of Kansas City’s concrete infrastructure.