When it comes to protecting and enhancing the appearance of concrete surfaces, the selection of the right sealant is crucial. Whether you’re working on a residential driveway, a commercial building, or an industrial facility in Kansas City, the choice of concrete sealant can make all the difference in the long-term performance and aesthetics of your project.

Understanding Concrete Sealants

Concrete sealants are specialized coatings designed to penetrate the surface of concrete and create a protective barrier. These products serve several essential functions, including:

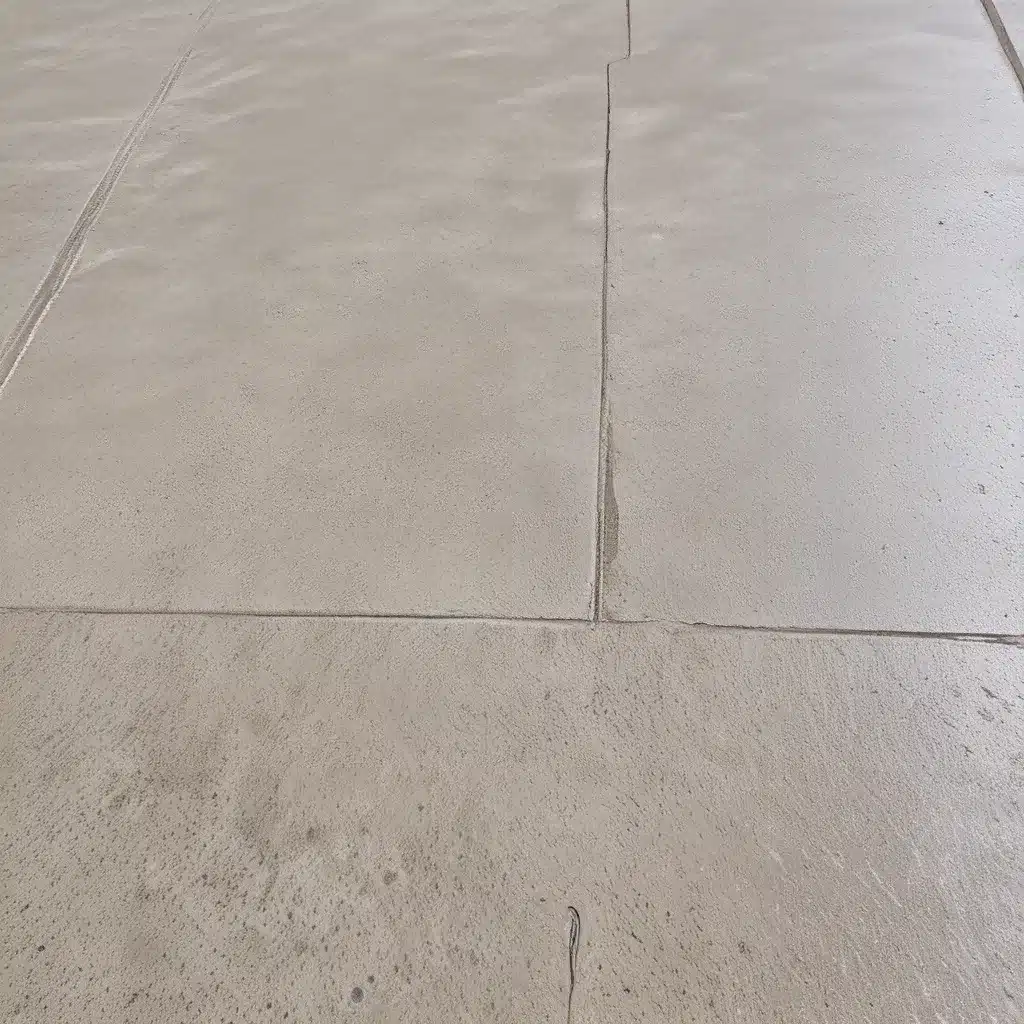

- Waterproofing: Sealants help prevent water intrusion, which can lead to cracking, spalling, and other forms of concrete damage over time.

- Stain and Chemical Resistance: Many sealants provide a barrier against oil, grease, and other common stains, as well as chemicals that could potentially harm the concrete.

- UV Protection: Some sealants contain UV-resistant additives to help prevent fading and discoloration from prolonged sun exposure.

- Enhanced Appearance: Concrete sealants can enhance the natural color and sheen of the surface, creating a more uniform and visually appealing finish.

Factors to Consider When Selecting a Concrete Sealant

When choosing the right concrete sealant for your project in Kansas City, there are several key factors to take into account:

1. Surface Preparation

Proper surface preparation is crucial for the success of any concrete sealant application. This may involve steps like etching, cleaning, and neutralizing the concrete to ensure optimal adhesion and penetration of the sealant.

2. Substrate Conditions

The existing condition of the concrete, including its porosity, texture, and any previous coatings or sealers, will influence the type of sealant that should be used. Smooth, dense concrete may require a different sealant than older, weathered concrete with greater porosity.

3. Application Environment

Factors like temperature, humidity, and exposure to UV rays can affect the performance of the sealant. Sealants with enhanced resistance to environmental stresses may be necessary for projects in harsher outdoor conditions.

4. Performance Requirements

Consider the specific needs of your project, such as durability, chemical resistance, or slip resistance. Some sealants are better suited for high-traffic areas, while others may be more appropriate for decorative or specialty applications.

5. Aesthetic Considerations

If maintaining or enhancing the visual appeal of the concrete is a priority, color-tinted sealants or products that offer a range of finishes (e.g., glossy, matte, or satin) can be valuable options.

Types of Concrete Sealants

The concrete sealant market offers a wide variety of products, each with its own unique properties and applications. Some of the most common types include:

Acrylic Sealers

Acrylic sealers are water-based or solvent-based coatings that provide a clear, durable finish. They are known for their ease of application and relatively low cost, making them a popular choice for many residential and commercial projects.

Epoxy Sealers

Epoxy sealers are two-component coatings that offer exceptional chemical resistance and durability. They are often used in industrial or high-traffic settings where strength and longevity are essential.

Silicone-Based Sealers

Silicone-based sealers are renowned for their water-repellent properties and UV resistance. They can be an excellent choice for outdoor applications exposed to the elements, such as driveways, patios, and parking structures.

Polyurethane Sealers

Polyurethane sealers provide a tough, long-lasting finish that is resistant to abrasion and weathering. They are commonly used in commercial and industrial settings, as well as for decorative concrete applications.

Penetrating Sealers

Penetrating sealers, such as AquaTint Colored Sealers, are designed to soak into the concrete and chemically react with the substrate, creating a durable, protective barrier without significantly altering the surface appearance.

Applying Concrete Sealants

Proper application of the chosen sealant is critical to ensure its long-term performance and effectiveness. This may involve:

- Surface Preparation: Cleaning, etching, and priming the concrete to ensure optimal adhesion.

- Application Techniques: Roller, spraying, or brush application, depending on the product and the surface.

- Curing and Drying Time: Allowing the sealant to fully cure before exposing the surface to traffic or use.

It’s important to follow the manufacturer’s instructions carefully and consider factors like temperature, humidity, and application methods to achieve the best results.

Maintaining Concrete Sealants

To extend the lifespan of your concrete sealant, regular maintenance is recommended. This may include:

- Periodic Reapplication: Depending on the sealant type and the level of wear and tear, you may need to reapply the sealant every 2-5 years to maintain its protective properties.

- Cleaning and Spot Repairs: Addressing any stains, cracks, or other surface issues promptly to prevent further damage.

- Protecting the Sealant: Avoiding the use of harsh chemicals, abrasives, or excessive foot/vehicle traffic that could compromise the sealant’s integrity.

By following these best practices, you can help ensure that your concrete surfaces in Kansas City remain protected, durable, and visually appealing for years to come.

Partnering with Concrete Professionals in KC

When it comes to selecting and applying the right concrete sealant for your project in Kansas City, it’s often beneficial to work with experienced concrete contracting professionals. These experts can provide valuable guidance on the selection of the appropriate sealant, ensure proper surface preparation and application, and offer ongoing maintenance recommendations to keep your concrete surfaces looking their best.

By leveraging the expertise of local concrete contractors in Kansas City, you can ensure the long-term success and performance of your concrete investment, whether it’s for a residential, commercial, or industrial application.